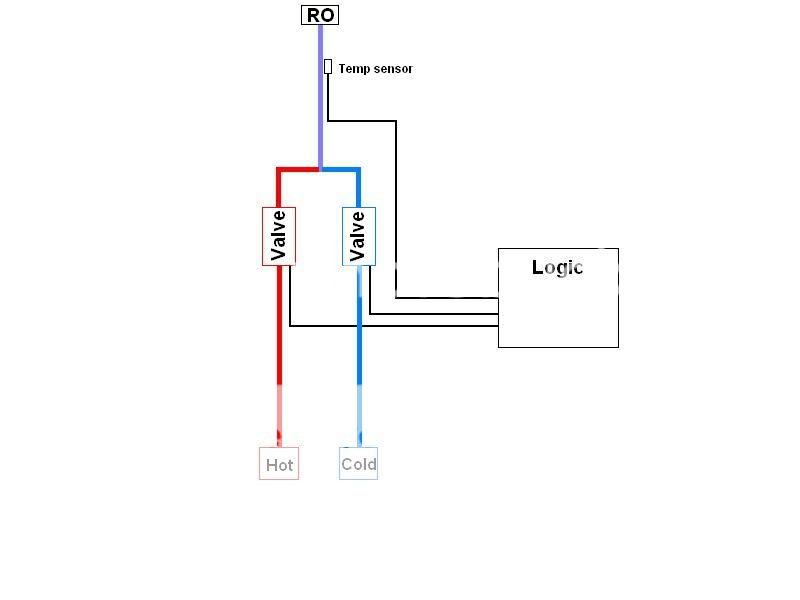

One thing I can not figure out. I purchased these solenoid valves. When I hook them up they work for a while and then quit. I remove the wires and reconnect them, they work again. I am thinking the wire is crap material and doesn't conduct very well? Really frustrating

Watch the pressure rating for the valves. I had nice industrial valves for my own setup, they were rated for around 80psi...I ran them at about 140psi. Worked for a bit, then the plunger would get cracked and it wouldn't work any more. Maybe the same is happening to you.