scooter4n

Established Member

Hello.

My best friend Dre, he is remodeler, he installs and makes in house cabinets and all that work. he told me and even started building me new cage for Rex. I was looking at allot of cages online, and after seating down with him, we got plan.

Cage will be 2'x2'x4'

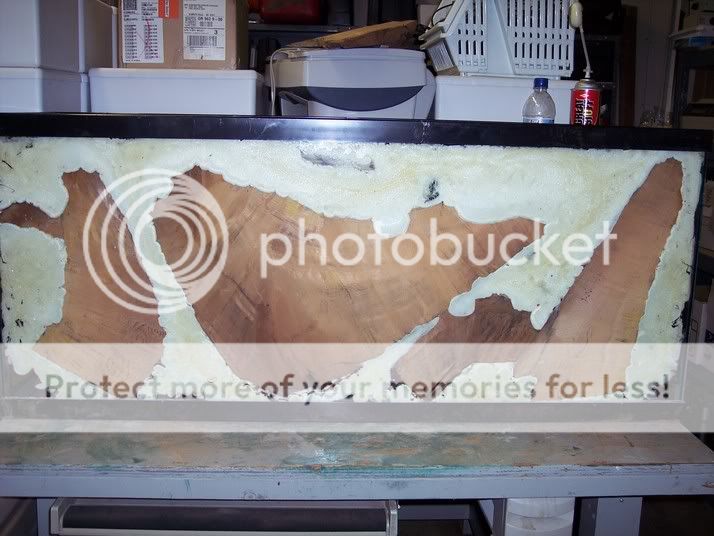

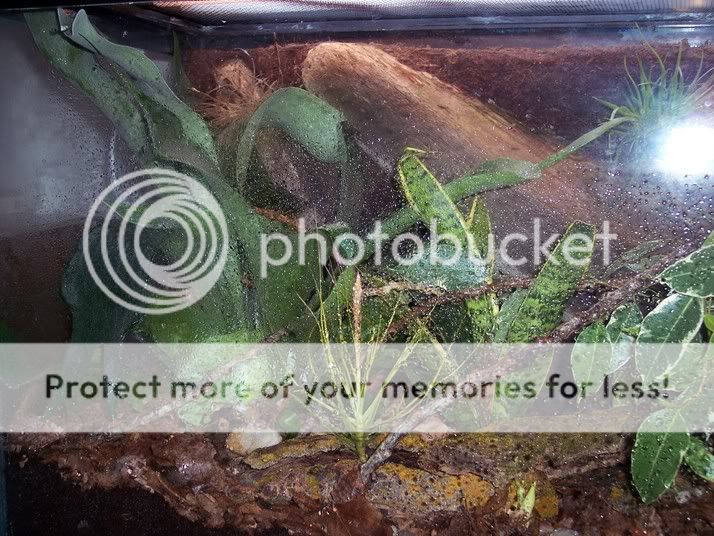

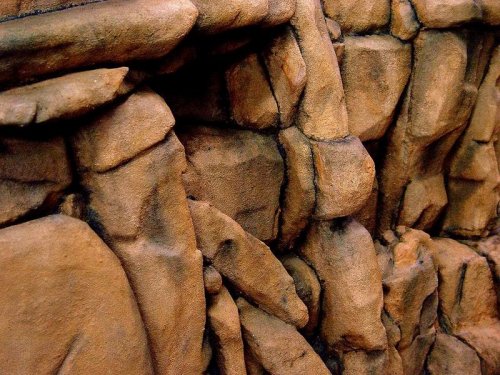

I'm looking in to very nice setups for inside of the cage. I'm thinking to make back wall like a rock wall, or something like it. Looking for ideas. If you seen something very interesting online, please post it. I want to make this cage look like part of the chameleon habitat, jungle like. Please bring it on.

Thanks

My best friend Dre, he is remodeler, he installs and makes in house cabinets and all that work. he told me and even started building me new cage for Rex. I was looking at allot of cages online, and after seating down with him, we got plan.

Cage will be 2'x2'x4'

I'm looking in to very nice setups for inside of the cage. I'm thinking to make back wall like a rock wall, or something like it. Looking for ideas. If you seen something very interesting online, please post it. I want to make this cage look like part of the chameleon habitat, jungle like. Please bring it on.

Thanks